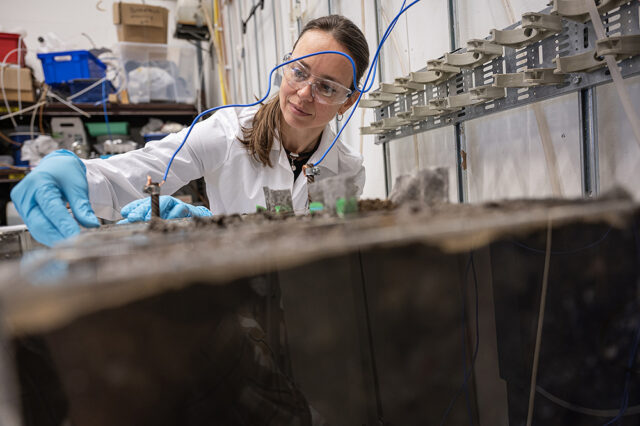

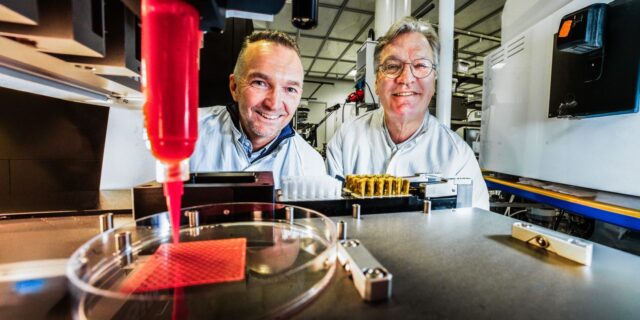

Credit: Imperial College London.

Multifunctional materials are engineered to do more than just one job. Take structural power composites, for example: they can both withstand mechanical loads and store energy. This unique combination has sparked growing interest in recent years, particularly in the transportation sector, where reducing vehicle weight and efficient energy storage are key to building more sustainable mobility solutions. But with such novel capabilities comes a challenge: there are no standardized ways to characterize or report on these materials. To tackle this gap, a team of WISE Guest Professors, WISE-affiliated researchers, and national and international collaborators recently shared their insights in a perspective article published in Advanced Energy Materials.

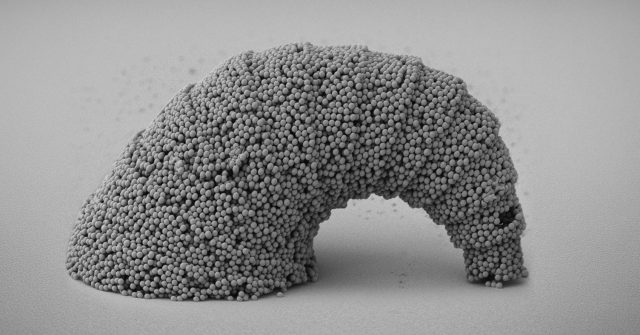

Multifunctional capabilities are not new; nature has been perfecting them for millions of years. In living organisms, very few structures serve a single purpose. Inspired by this, researchers see multifunctional materials as a way to design products that use less energy, fewer resources, and generate less waste. In their recent article “Characterization and Reporting Protocols for Structural Power Composites: A Perspective,” Prof. Leif Asp (Chalmers University of Technology and WISE-affiliated researcher), WISE Guest Professors Madhavi Srinivasan (Nanyang Technological University) and Alexander Bismarck (University of Vienna), together with national and international collaborators, focus on a promising class of materials: structural power composites (SPCs). These are mechanically load-bearing fiber-reinforced polymer composites that can also store and deliver electrical energy. (Curious about composite materials? Scroll to the end of the page.)

Structural power composites

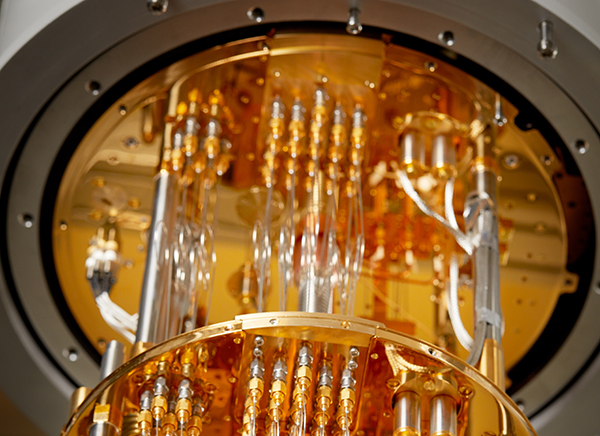

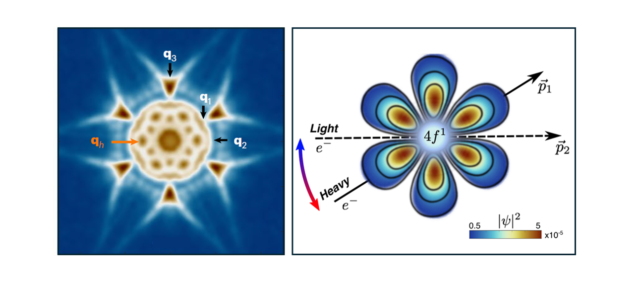

SPCs work much like conventional supercapacitors and batteries in their architecture and charge-storage mechanisms, but with a surprising twist. Their components, such as structural electrodes and structural electrolytes, are designed to carry mechanical loads. This multifunctionality has propelled SPCs into the World Economic Forum’s Top 10 Emerging Technologies of 2025. Potential applications range from phones as thin as credit cards to aircraft seats that power the cabin, and even “structural battery bricks” that could store energy for entire homes.

—Imagine a world where vehicles, buildings, and even everyday devices become self-powering, seamlessly merging structure and storage. This is the vision of structural power composites. Developing structural power composites requires us to rethink both electrochemical and mechanical design principles. By integrating load-bearing capability with energy storage in a single material, we are addressing two traditionally separate challenges at once. Structural power composites open the door to a future where every part of a product contributes not only to its form and strength, but also to its function as an energy source, says WISE Guest Professor Madhavi Srinivasan from Nanyang Technological University.

The challenge of reporting results

As with many emerging fields, SPC research faces significant hurdles in how performance is measured and reported. The challenge is amplified by the interdisciplinary nature of the field: the standards and conventions used in electrochemistry differ widely from those in mechanical engineering. Recognizing this, the authors emphasize that developing shared characterization methods, reporting protocols, and best practices is a critical priority.

—This work represents a joint effort by the national and international scientific community leading the development of SPCs, aiming to establish the requirements needed to produce such protocols, says Professor Leif Asp from Chalmers University of Technology and WISE-affiliated researcher.

Looking ahead, these innovative materials could reshape infrastructure, energy storage, and product design across multiple industries within the next decade.

Read more about the article: Characterization and Reporting Protocols for Structural Power Composites: A Perspective. [Adv. Energy. Mat. e04702 (2025)]. https://advanced.onlinelibrary.wiley.com/doi/full/10.1002/aenm.202404702

Read the full report of the World Economic Forum at: https://www.weforum.org/publications/top-10-emerging-technologies-of-2025/in-full/structural-battery-composites/

To read more on Prof. Asp’s research at WISE visit:

Graphene-enhanced structural battery composites for future energy storage

(*) Composite materials are made by combining two or more different materials with different properties that stay separate within the final structure. Together, they create a new material with improved properties that neither component has on its own. The most common structural composites use strong reinforcement fibers—like carbon, glass, or aramid—embedded in a polymer matrix. The fibers provide stiffness and strength, while the matrix holds everything together and transfers loads.