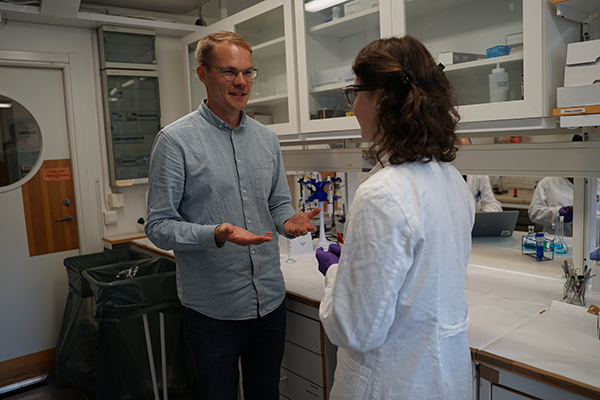

Enter a groundbreaking collaboration between the company Retein, Chalmers University of Technology, and WISE (Wallenberg Initiative Materials Science for Sustainability), where science meets sustainability in a bold new way. We spoke with Simon Isaksson, CEO and founder of Retein, who is also one of the principal investigators of an industrial PhD research project at WISE.

The Spark Behind the Partnership

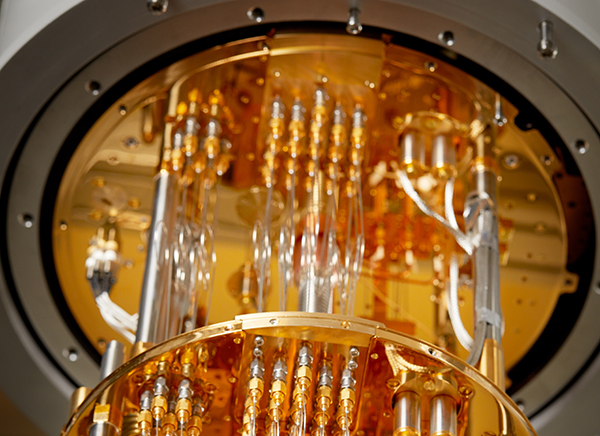

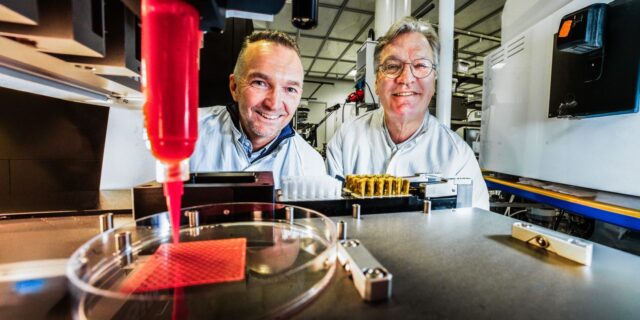

Retein, a company known for its innovative water filtration technologies, had a vision: to recover lithium from industrial wastewater in a way that’s both efficient and environmentally friendly. But turning that vision into reality required deeper scientific insight. That’s where WISE and Chalmers came in. With support from Professor Martin Andersson, Wallenberg Academy Fellow and Principal Investigator of the WISE project, the team launched an industrial PhD project to explore a novel idea — using proteins to selectively extract lithium from water.

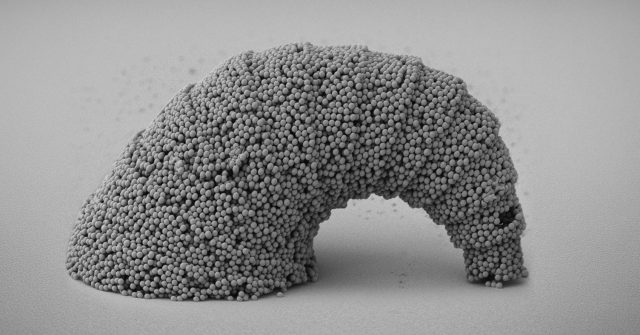

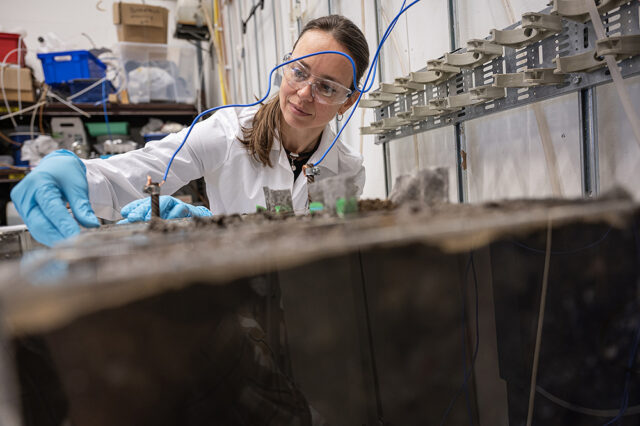

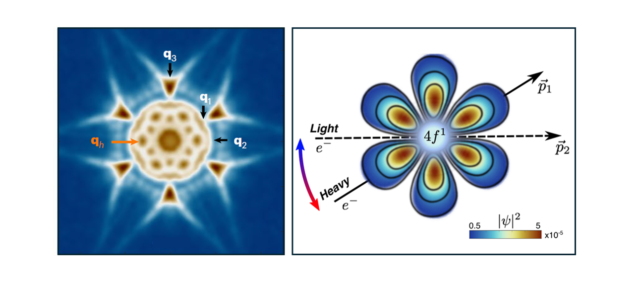

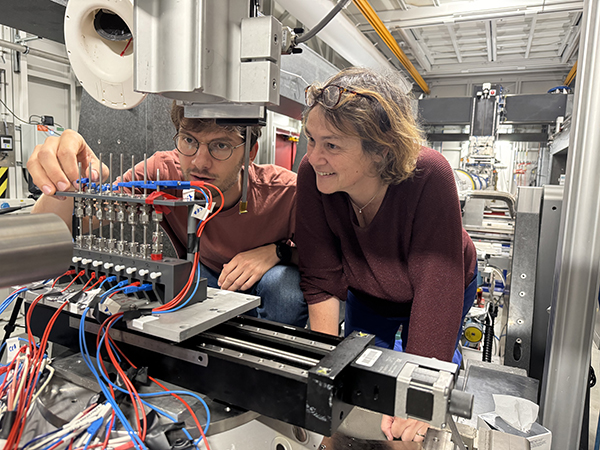

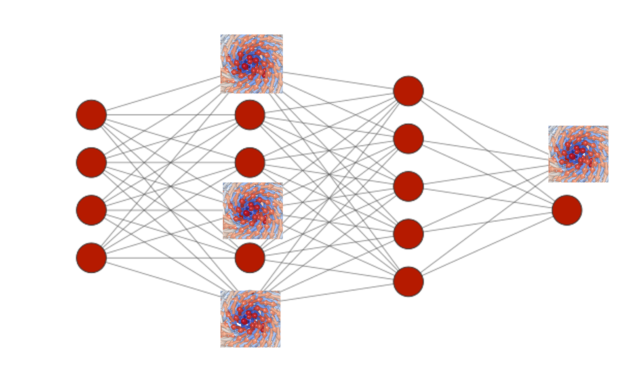

The project’s core ambition is to harness the natural selectivity of proteins to recover lithium from complex water mixtures. But it’s not as simple as dropping proteins into a filter. Researchers are working to stabilize these proteins and embed them into separation membranes—a delicate process that could unlock a new frontier in sustainable materials science.

Why It Matters for the Planet

As the demand for sustainable and efficient lithium recovery grows, innovative solutions are essential to address the environmental and energy challenges of traditional methods.

“Lithium recovery today often involves energy-intensive processes and harsh chemicals. This project aims to change that. By using bio-based methods, the team hopes to boost recovery yields while cutting down on energy use and chemical waste. That’s a win not just for industry, but for the environment—and ultimately, for all of us, says Simon Isaksson.

Who Stands to Benefit?

According to Simon the implications are vast.

“Industries involved in battery recycling, battery manufacturing, and electric vehicles could see major gains. More efficient lithium recovery means less reliance on mining, lower costs, and a smaller environmental footprint. And for consumers? It could mean greener gadgets and cleaner transportation.

“So far, the project has progressed as expected, with steady breakthroughs in methodology and performance. While no major surprises have emerged yet, the team is optimistic about what’s ahead. The next big milestone? A fully functional lithium recovery filter. Beyond the lab, this research touches on a bigger question: How do we build a sustainable future? Collaborations like this one are essential. They bridge the gap between academic research and industrial innovation, helping shift our systems from linear consumption to circular resource use.”

A Personal Mission

For those behind the project, sustainability isn’t just a professional goal—it’s personal. The drive to protect nature and reduce exploitation fuels both their scientific curiosity and their commitment to change. As one team member put it, “Preserving nature means preserving the joy of kayaking and hiking—for ourselves and future generations.”

Even if you’ve never heard of materials science, its impact is all around you. From cleaner batteries to safer water, it’s shaping the future in ways that matter. And this project? It’s a glimpse into how science can solve real-world problems—quietly, powerfully, and sustainably.