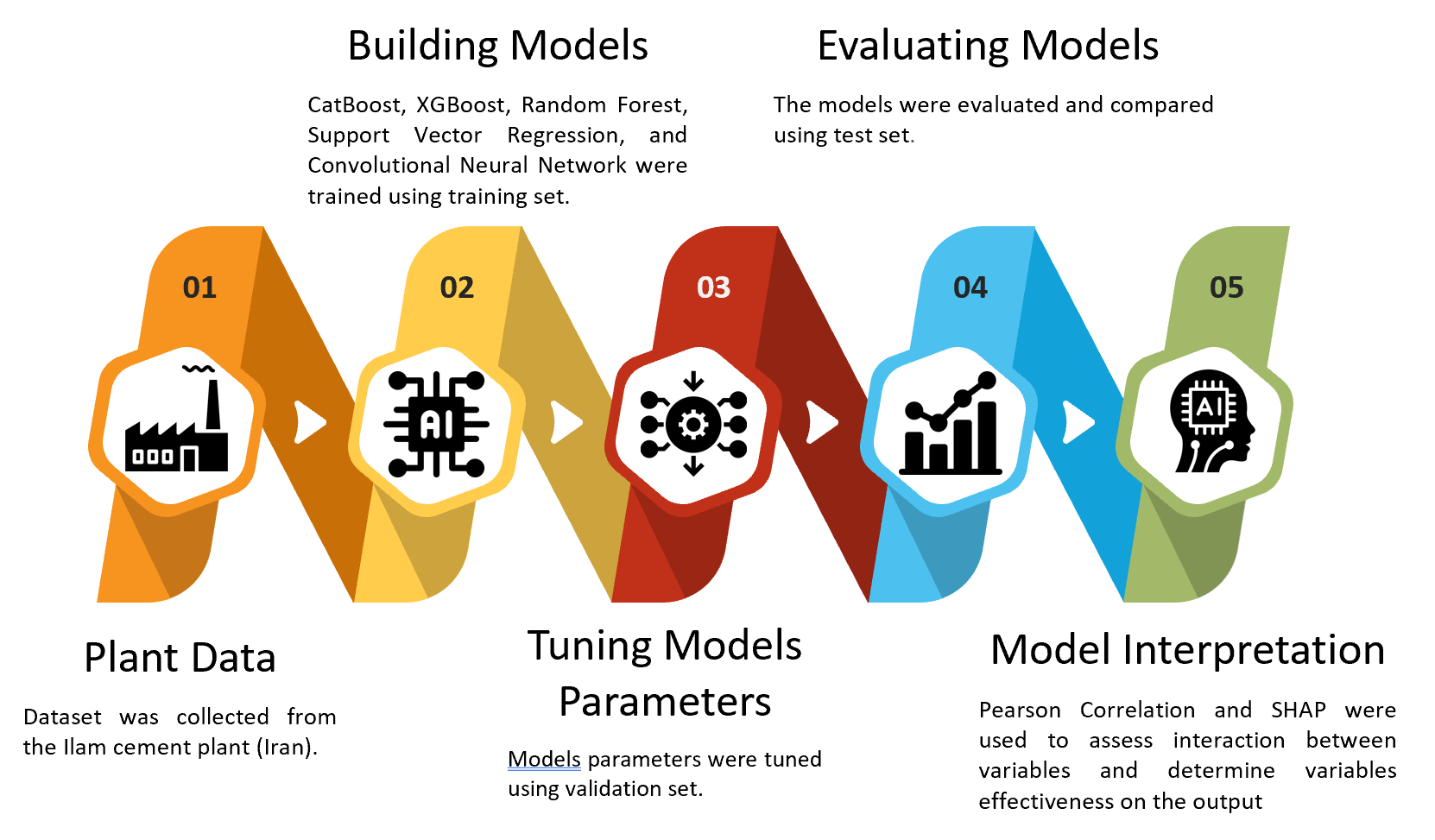

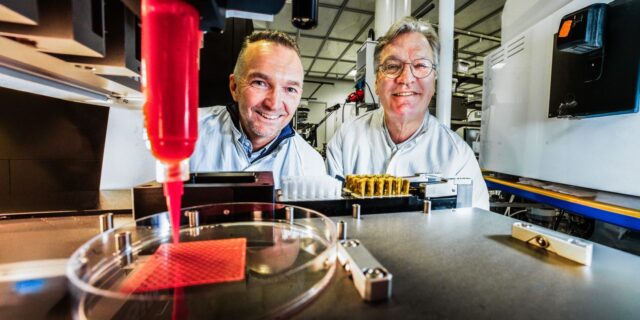

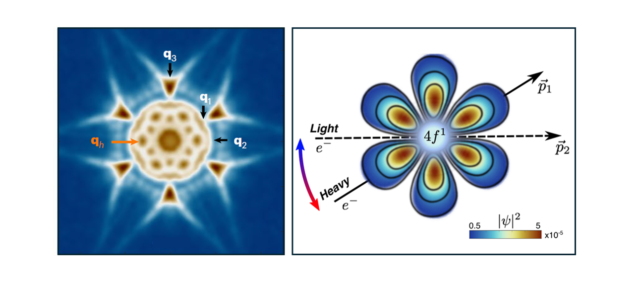

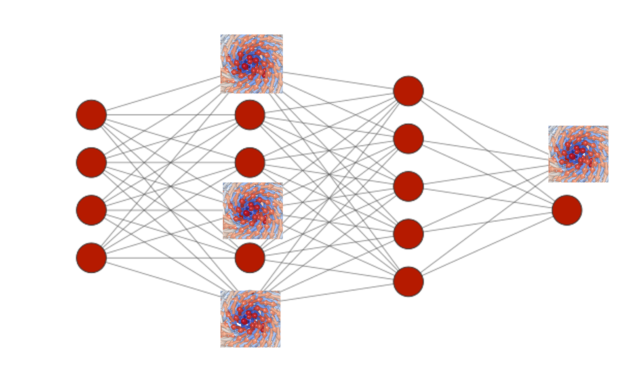

The figure shows the EAI scheme utilized in the study.

The rise of Industry 4.0 is reshaping the way we understand industry, as digital technologies such as the Internet of Things, Artificial Intelligence (AI), cloud computing, and advanced robotics become increasingly embedded in industrial processes. Yet despite the vast amounts of data industries now collect, much of it remains underused, leaving valuable opportunities for improving performance untapped. Using the cement industry as a case study, researchers at Luleå University of Technology have shown how Explainable Artificial Intelligence (EAI) can unlock this hidden potential.

In a recent study published in Scientific Reports, Professor Saeed Chehreh Chelgani and his colleagues tackled one of the industry’s most pressing challenges: energy efficiency.

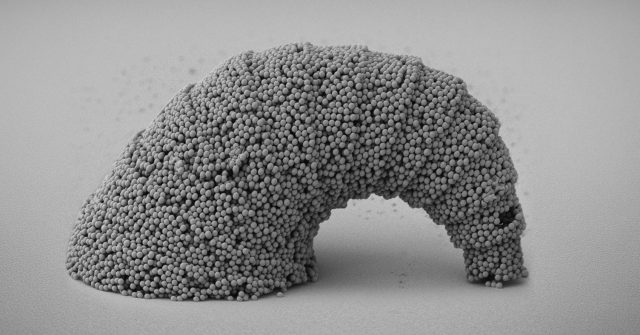

Cement production accounts for around 5% of global industrial energy use. In cement plants, nearly half of that energy is consumed by mills grinding raw materials into fine particles. But the process is notoriously inefficient — only about 5% of the energy is effectively used for particle size reduction, with the rest lost.

“Grinding in the cement industry is one of the most energy-intensive steps, and improving it is crucial for the green transition and sustainable production”, says Prof. Chelgani at Luleå University of Technology and WISE-affiliated researcher.

The Conscious Lab

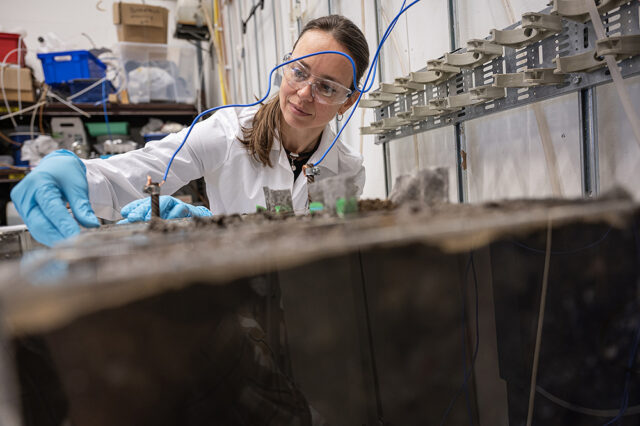

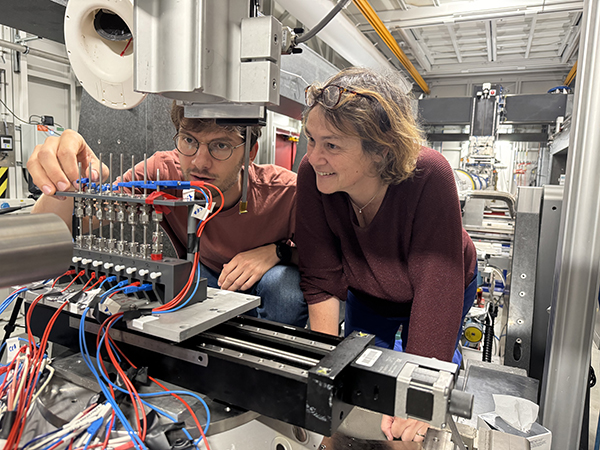

Understanding correlations between operational parameters and the mill energy consumption factors obtained directly from data recorded by sensors in production-lines can significantly help improve grinding processes. Prof. Chelgani’s team applied what they call a “conscious lab”, an EAI framework for industrial-scale problems that can reduce the complexity of such correlations and hence decrease randomness in griding processes, using real-world sensor data from a production plant.

“All data is valuable — even errors”, explains Chelgani. “With EAI methodologies, we can analyze it to discover how to improve industrial processes.”

The study shows that such AI-driven models could be used to train operators, optimize process control, save time and energy, reduce laboratory testing, and ultimately improve sustainability across the cement sector.

Chelgani also believes materials science as a field is still catching up when it comes to leveraging AI. “That is why I think the WASP-WISE calls are great opportunities to speed up development,” he says.

The team’s study, Modeling energy consumption indexes of an industrial cement ball mill for sustainable production (Scientific Reports 15, 18514, 2025), is part of the WASP-WISE project led by Prof. Chelgani.

Modeling REE interactions by Explainable AIs

Read the full article here: Nature Scientific Reports link.

More about Chelgani’s WISE projects can be found

Generating green functionalized magnetic microparticle depressants for enhancing Li battery recycling process