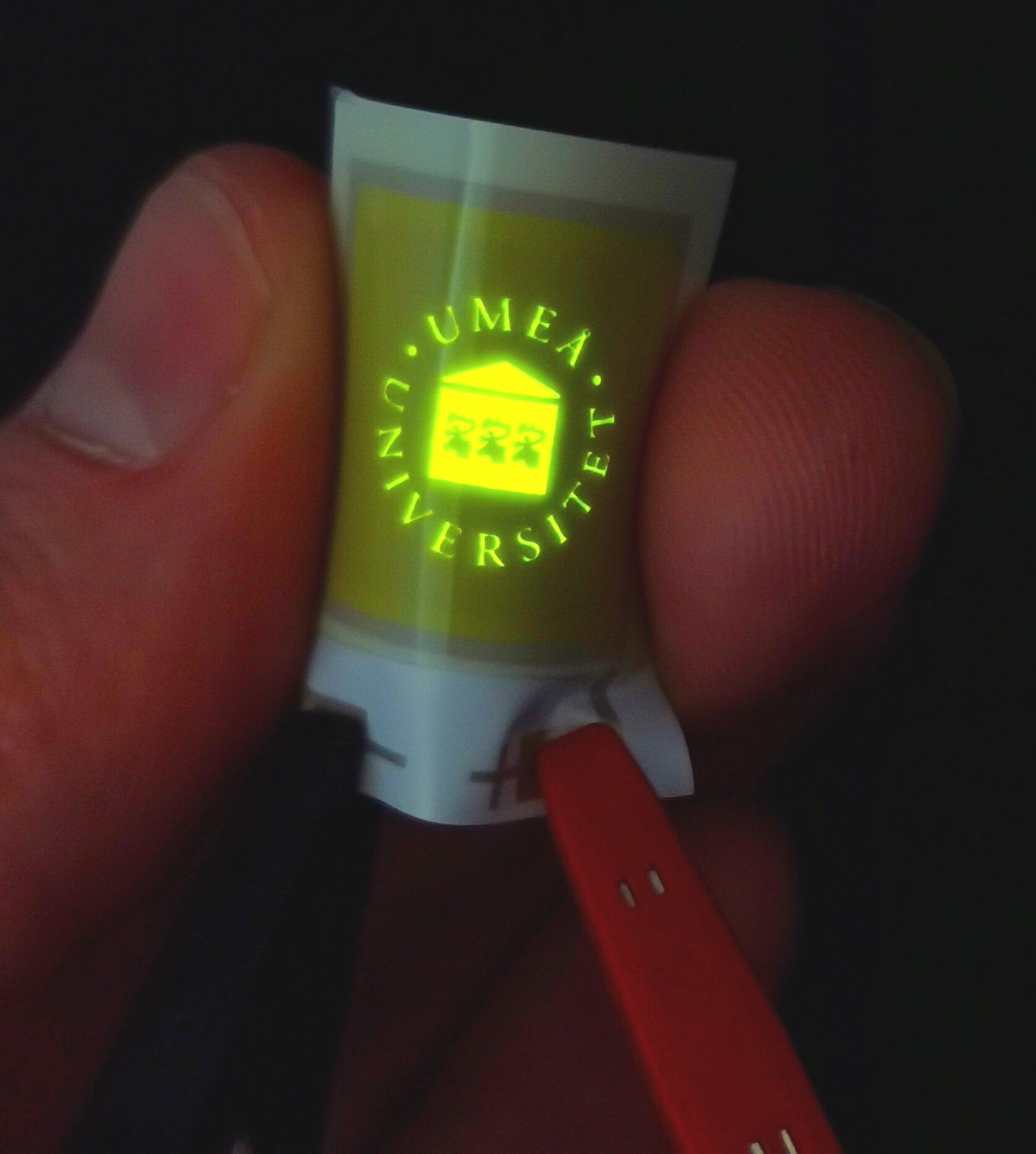

The commercial introduction of the light-emitting diode (LED) has revolutionized how we can efficiently illuminate our surroundings, while the development of the organic LED (OLED) enables high-quality displays such as those in our cell phones. The light-emitting electrochemical cell (LEC) is an emerging technology that offers the same attractive features as the OLED in the form of thin-film and flexible device architectures and vibrant and tunable emission colors.

In contrast to both LEDs and OLEDs, LECs can be fabricated by material-efficient and low-energy printing and coating methods. Furthermore, LECs can be fabricated completely free from critical raw materials and rare metals. These are obvious advantages from a sustainability perspective, however a drawback with current LEC devices is that the emission efficiency drops with increasing current in a process termed “efficiency roll-off”.

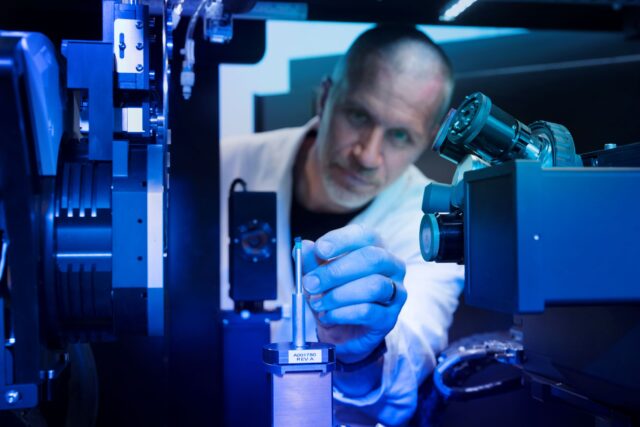

Professor Ludvig Edman and his team at Umeå University, in collaboration with researchers at Uppsala University and RISE, have recently addressed this issue in their scientific article, “Efficiency Roll-Off in Light-Emitting Electrochemical Cells,” published in April 2024, in the journal Advanced Materials [Adv. Mat. 36, 2310156 (2024)]. This article introduces a novel and practical method for understanding and quantifying the efficiency losses in LEC devices.

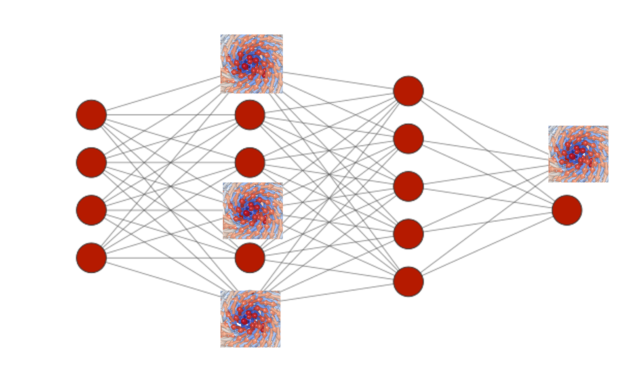

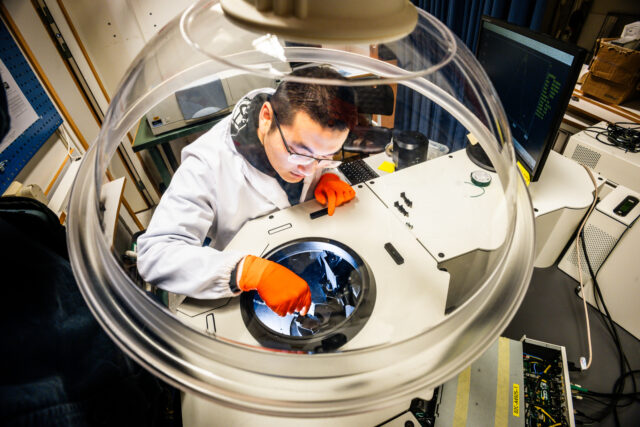

– We identified the mechanism behind the decreased light emission efficiency with increasing current, as being due to an increased probability for quenching collisions between the electronic charger carriers and the excitons (the precursor of the photons) in the emissive p-n junction region, explains Xiaoying Zhang, a PhD student at the Department of Physics at Umeå University and first author of the study.

The full article can be found at: https://doi.org/10.1002/adma.202310156

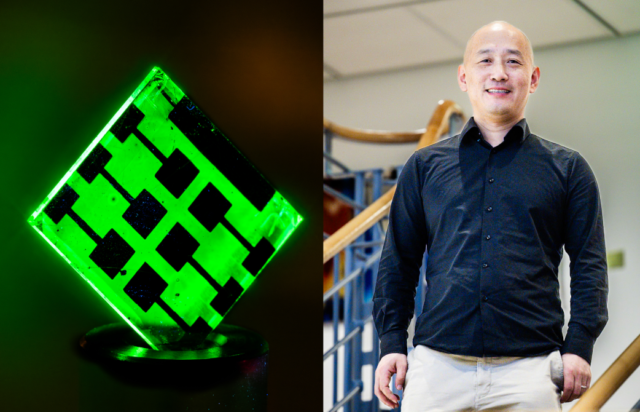

Professor Ludvig Edman is the leader of the Organic Photonics and Electronics Group at Umeå University, a WISE researcher, and he also represents the WISE affiliated group of excellence at Umeå University.

-Our recent demonstration that flexible and thin LECs can be fabricated using energy- and material-efficient printing in low-cost facilities, avoiding critical raw materials, has opened many possibilities. Our WISE project’s goal is now to develop tools for the rational tuning of the LEC’s unique dynamic p-n junction doping structure to improve the emission efficiency, using sustainable processes and bio-based and/or recyclable materials,” says Prof. Ludvig Edman at Umeå University.

Professor Edman’s WISE project can be found at:

A sustainable light-emission technology through control of dynamic doping