Organic electronics are made from semiconducting plastics, also known as conjugated polymers. In recent years, the importance of conjugated polymers has grown significantly, because of their potential to complement -and even replace -conventional silicon-based electronics. Their simple manufacturing process, high flexibility, low weight, and electrical properties akin to conventional semiconductors make them valuable for various applications, including digital displays, energy storage, solar cells, sensors, and soft implants.

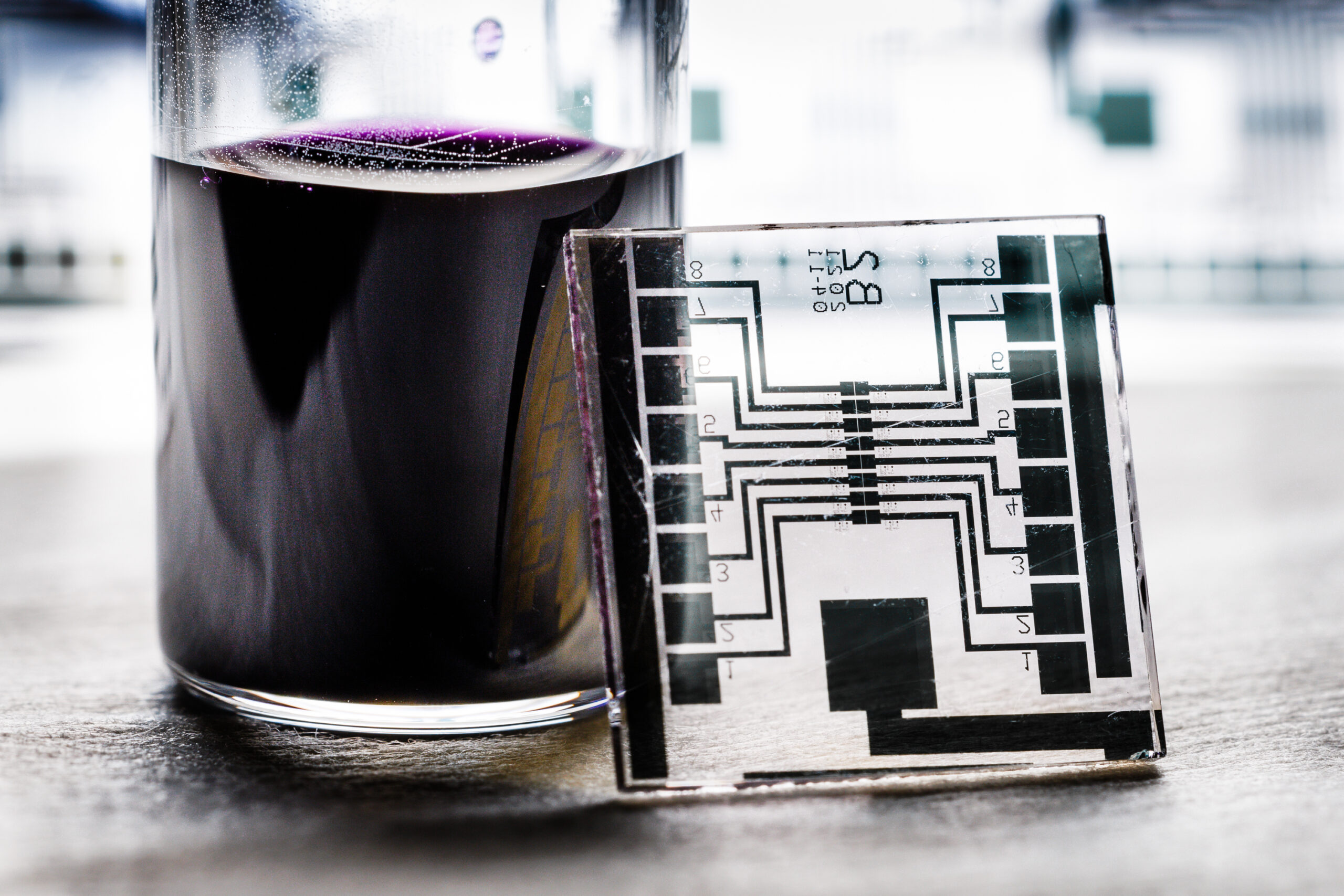

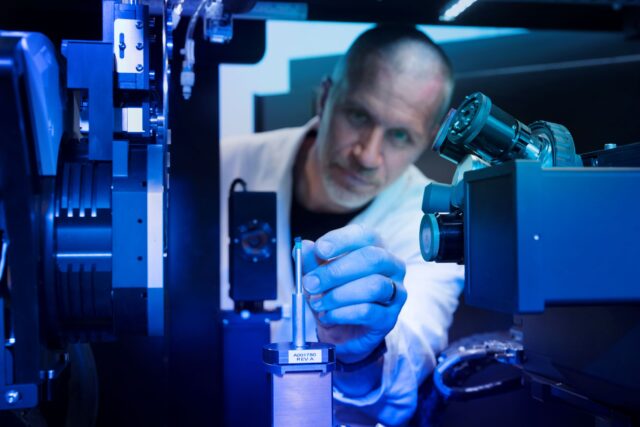

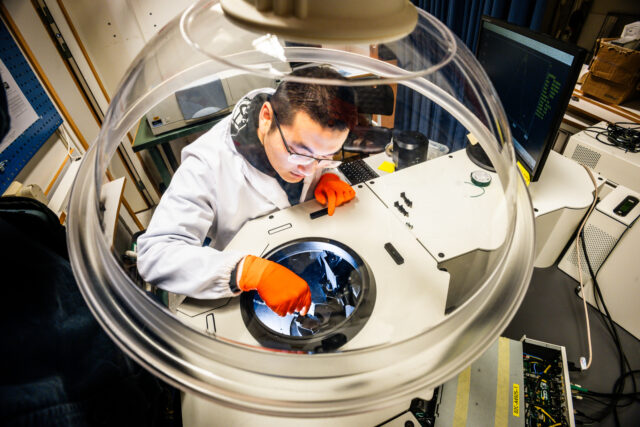

However, a major barrier to the widespread adoption of these materials has been the need for environmentally hazardous, toxic, and flammable solvents during processing. Addressing this issue, a recent study published in Nature Communications by researchers affiliated with WISE, led by Prof. Simone Fabiano at Linköping University, introduced a sustainable method for processing these polymers using water-based inks. Additionally, to using more benign solvents, these new inks exhibit significantly enhanced conductivity, surpassing pristine polymers by a factor of 10,000.

-Our research introduces a new approach to processing conjugated polymers using benign solvents such as water. With this method, called ground-state electron transfer, we not only get around the problem of using hazardous chemicals, but we can also demonstrate improvements in material properties and device performance,” explains Simone.

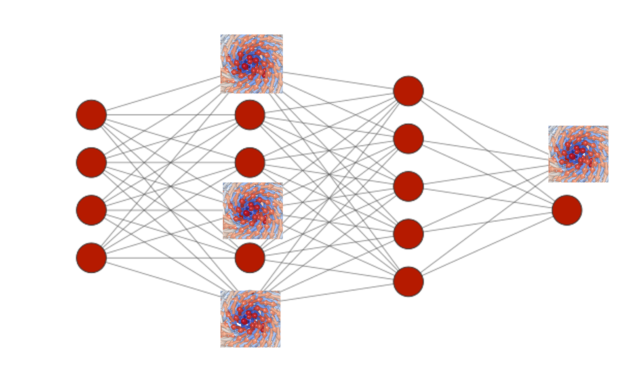

Testing the new conductive ink as a transport layer in organic solar cells revealed higher stability and efficiency compared to traditional materials. Moreover, the ink was utilized to fabricate electrochemical transistors and artificial neurons, exhibiting operational frequencies like biological neurons.

This article is based on a press release by Liköping University, https://liu.se/en/news-item/miljovanligare-metod-for-att-skapa-organiska-halvledare

Read more: https://www.nature.com/articles/s41467-023-44153-7

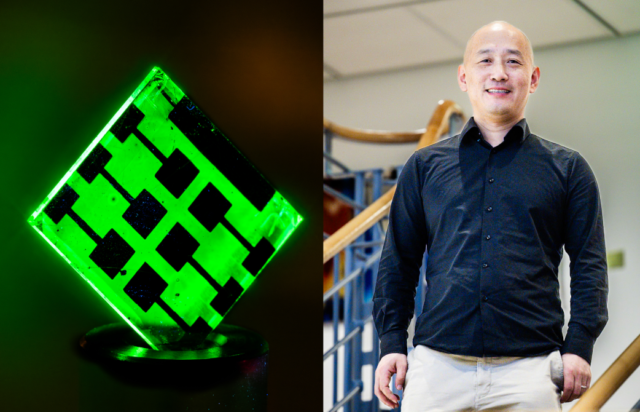

Industrial development of environmentally friendly inks

Prof. Simone Fabiano is leading an industrial research project at WISE in collaboration with N-ink AB. This project aims to leverage water-soluble n-type conductive polymers to create a versatile material serving as both an electron transport layer and a low-work function electrode. This innovative material class is expected to enhance power conversion efficiency and longevity while simplifying the construction of organic photovoltaic stacks through the use of environmentally friendly and sustainable inks.

– With this WISE project we expect to contribute to speed up the commercialization of these new water-based inks for photovoltaics devices, says Prof. Fabiano.

Read more:

TeraSolar

https://www.n-ink.com/