2 Feb 2026

WASP–WISE NEST 2 Joint Call Now Open

WASP and WISE hereby announce the WASP–WISE 2026 call for NEST 2 (Novelty, Excellence, Synergy, and Teams) is open.

3 Oct 2025

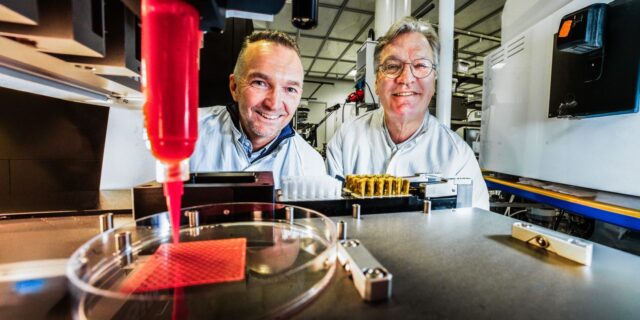

On 2 October 2025, Chalmers University of Technology officially inaugurated its new additive manufacturing infrastructure: AM@Chalmers and the Chalmers WISE Additive node.

This open research platform offers advanced capabilities in metal and multi-material 3D printing, designed to support both academic research and industrial innovation.

“Additive manufacturing is evolving rapidly and is already making a significant impact in industries like aerospace, biomedical, and energy. With this new infrastructure, both researchers and industry gain access to the full spectrum of powder-based metal and multi-material additive manufacturing technologies,” says Eduard Hryha, director of AM@Chalmers and CAM2, Centre for Additive Manufacture – Metal.

A Hub for Research, Education and Industry Collaboration

Additive manufacturing—often referred to as industrial 3D printing—builds components layer by layer, allowing for lightweight, complex, and multifunctional designs that traditional methods can’t achieve. However, broader adoption has been limited by access to high-end technology.

Árni Halldórsson, Director of Production Area of Advance at Chalmers, emphasizes the strategic importance:

“AM@Chalmers helps build critical mass in research and innovation. Beyond efficiency, it enhances flexibility and responsiveness—key for delivering customized solutions in uncertain times.”

National Collaboration Through WISE Additive

The Chalmers WISE Additive node is part of a national initiative funded by the Wallenberg Initiative Materials Science for Sustainability (WISE), alongside nodes at Uppsala University and Linköping University.

Cecilia Persson, Scientific Director of WISE Additive at Uppsala University, highlights the collaborative benefits:

“This collaboration across several universities facilitates external access to research infrastructure in an efficient way, which we hope will lead to additive manufacturing enabling more sustainable materials science.”

Maria Abrahamsson, WISE Coordinator at Chalmers, adds:

“We are very happy that WISE is able to provide researchers from all over Sweden access to this state-of-the-art infrastructure, at Chalmers as well as at the other nodes. I believe this to be an impactful investment that can really make us take big steps toward more sustainable production.”

Driving Innovation in Materials and Manufacturing

The new infrastructure enables exploration of novel material combinations and microstructures, unlocking new applications across industries.

“Sweden already has a strong footprint in additive manufacturing and is a recognized leader in metal powder production. But we’ve only scratched the surface of what’s possible. This infrastructure aims to provide a breeding ground for future innovation and help accelerate the development and industrial implementation,” says Eduard Hryha.

2 Feb 2026

WASP and WISE hereby announce the WASP–WISE 2026 call for NEST 2 (Novelty, Excellence, Synergy, and Teams) is open.

27 Jan 2026

WISE Dialogue 2026 is approaching – the major annual gathering for the entire WISE community!

20 Jan 2026

Don’t miss the chance to hear from two internationally renowned researchers in an upcoming digital seminar on February 5, 2026, from 3-4 pm CET.

16 Jan 2026

WISE is preparing its 3rd Academic Project Call (WISE-ap3) to fund PhD and postdoc research advancing sustainable, eco-friendly materials and manufacturing processes.

22 Dec 2025

“Sustainability is at the center of everything we do. Our research focuses on some of the greatest challenges of our time – such as how we extract raw materials, use energy, deal with emissions and reduce waste.”

Photo credit: Thor Balkhed, Linköping University

16 Dec 2025

Research on organic solar cells at Karlstad University is advancing with support from WISE.

15 Dec 2025

On February 2, 2026, WASP and WISE will launch a joint call for proposals for five-year NEST projects.

11 Dec 2025

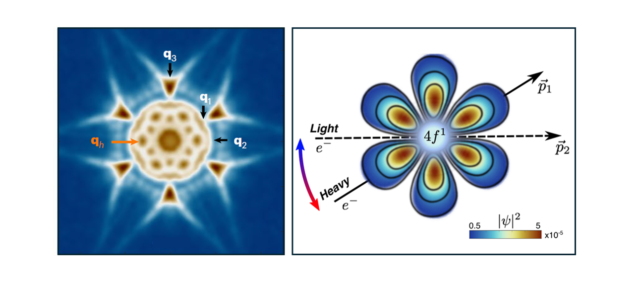

“Ce-based systems continues to surprise us in their unique physical and chemical properties, and the current discovery certainly should be placed under WISE thematic area Discovery, with hope to become a key ingredient in applications for sustainability”, says Prof. Eriksson from Uppsala University and WISE co-director.

5 Dec 2025

“For us it is important to work with sustainable materials and make sure that we manufacture them employing low-energy processes. We think from the beginning what elements we are going to use -their availability, price, recycling possibilities, etc.”, says Professor Thelakkat.

28 Nov 2025

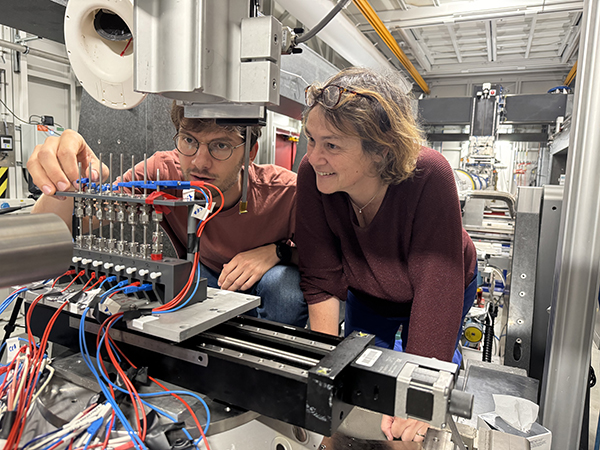

The Uppsala node of the WISE Additive Research and Technology Platform (RTP) was officially inaugurated this week, marking a significant step in strengthening Sweden’s national research capacity in additive manufacturing.

Picture credit: Tobias Sterner, Bildbyrån

25 Nov 2025

Energy storage is one of the great scientific challenges of our time. To move toward a more sustainable society, we need batteries that are not only efficient but also environmentally responsible.

20 Nov 2025

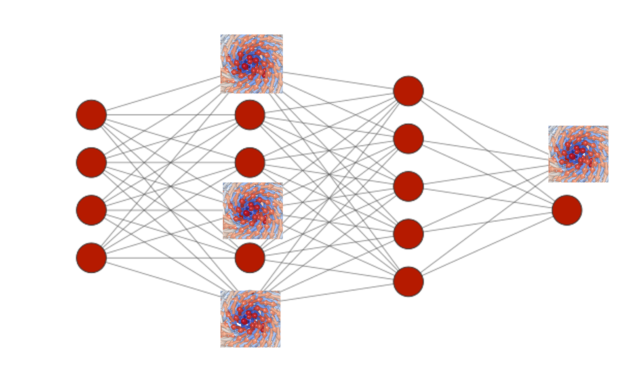

Join us for the 7th Machine Learning Meets Materials Science Seminar, part of the WASP–WISE initiative! Mark your calendars: November 26 at 10:00!

17 Nov 2025

Uppsala University’s WISE Symposium series will spotlight cutting-edge sustainability research on November 26, 2025, with a webinar dedicated to the environmental aspects of additive manufacturing.

12 Nov 2025

On December 4, 2025, from 15:00 to 16:00, Uppsala University will host a WISE Guest Professor Lecture featuring Professor Julie Beth Zimmerman and Dr. Sandrine Lyonnard, both WISE Guest Professors at the university.

11 Nov 2025

“This talk explores the emerging frontier of biotechnology in enabling greener battery technologies, specifically through biohydrometallurgy and bio-based materials, ” says Prof. Srinivasan Nanyang from the Technological University (NTU), Singapore.

10 Nov 2025

As part of WISE’s Guest Professor (GP) program — one of our key initiatives to foster international collaboration and enrich student learning — we are delighted to welcome Professor Mette Rica Geiker from the Norwegian University of Science and Technology (NTNU) to Chalmers University of Technology.

Picture by Ann-Marie Thoresen at Statens Vegvesen

6 Nov 2025

The inauguration of the WISE Additive node at Linköping University (LiU) took place this week, marking an important milestone in the development of Sweden’s research infrastructure for additive manufacturing and soft electronics for sustainability.

Picture by Thor Balkhed, Linköping University

3 Nov 2025

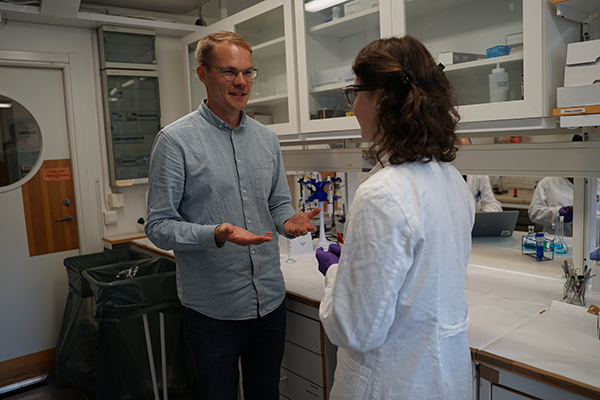

The Guest Professor (GP) program is one of WISE’s recruitment and outreach activities, designed to foster international research collaborations and support the development of our students.

27 Oct 2025

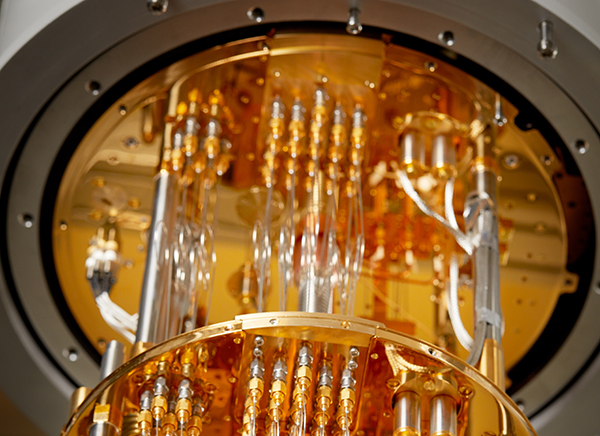

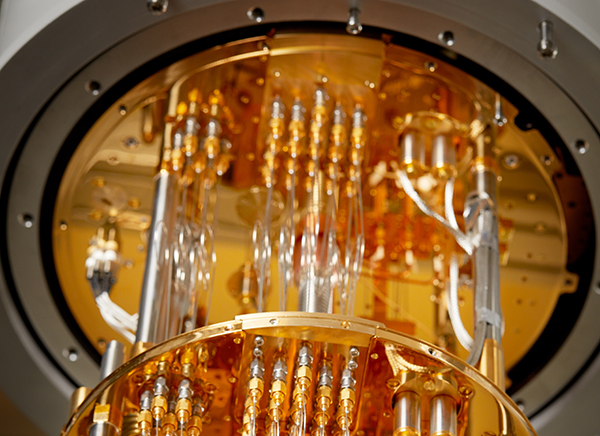

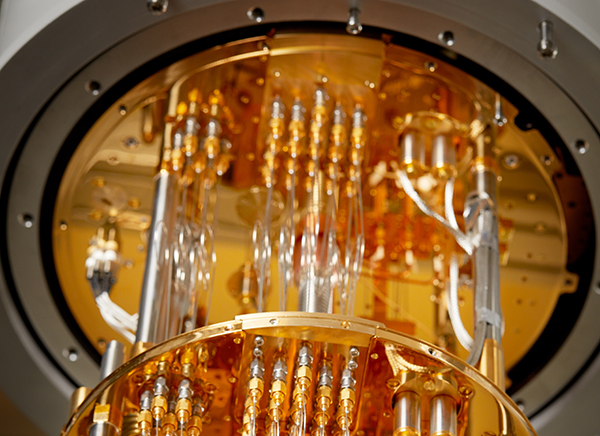

The Wallenberg Centre for Quantum Technology (WACQT) and the Wallenberg Initiative Materials Science for Sustainability (WISE) have launched a new call for proposals — now open for applications!

23 Oct 2025

“Our society is increasingly dependent on technology. Take smartphones, for example: our entire lives are stored in them. Yet most of us are unaware of how energy-intensive their production processes are, how toxic or scarce some of the materials used in these devices can be, or how poorly many technologies are designed for recycling”, says WISE Guest Professor Federico Rosei at LTU.

22 Oct 2025

The Wallenberg Initiative Materials Science for Sustainability (WISE) seeks a Director of Sustainability to lead and develop the initiative’s strategic sustainability efforts.

20 Oct 2025

“I think it is important to observe and learn from nature. Nature does not waste. What one organism discards, another uses as energy. The key question for us is how we can minimize and reuse our own waste, how we can create more with less”, says WISE Guest Professor Alexander Bismarck from University of Vienna.

16 Oct 2025

We’re thrilled to kick off the WACQT-WISE Pilot Call 2025 with an inspiring webinar.

14 Oct 2025

—Quantum phenomena and materials science have once again demonstrated unique phenomena with the potential to benefit society, says Professor Olle Eriksson at Uppsala University, WISE Co-Director and Chair of the Nobel Committee for Physics.

9 Oct 2025

In a world increasingly powered by lithium-ion batteries—from smartphones to electric vehicles—the race is on to find cleaner, smarter ways to recover this critical metal.

Photo taken by Retain.

3 Oct 2025

The Wallenberg Centre for Quantum Technology (WACQT) and the Wallenberg Initiative Materials Science for Sustainability (WISE) are launching a new call to spark collaboration at the cutting edge of research.

2 Oct 2025

—Imagine a world where vehicles, buildings, and even everyday devices become self-powering, seamlessly merging structure and storage. This is the vision of structural power composites. Structural power composites open the door to a future where every part of a product contributes not only to its form and strength, but also to its function as an energy source, says WISE Guest Professor Madhavi Srinivasan from Nanyang Technological University.

25 Sep 2025

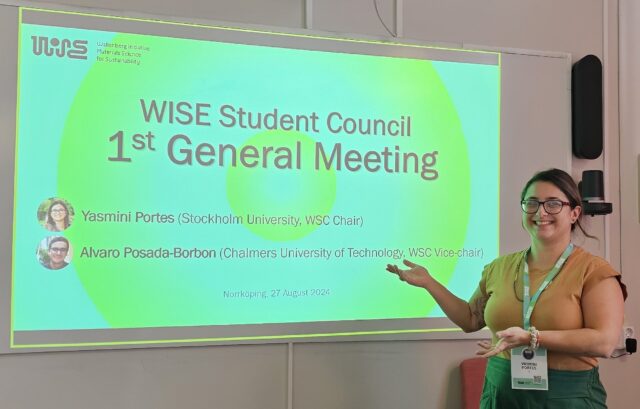

-Our role is to act as a bridge between PhD students, postdocs, and WISE Research School management. We receive questions and concerns both from students and postdocs as well as from the RS management, which we bring to our meetings for discussion, says Yamini Portes, chairperson of the WISE Student Council and PhD student at Stockholm University.

24 Sep 2025

Join us for the 6th Machine Learning Meets Materials Science Seminar, part of the WISE–WASP initiative! Mark your calendars: October 1 at 10:00!

24 Sep 2025

We’re pleased to announce that registration is now open for the AM4Life/WISE Additive Autumn School on the theme “Post-processing in AM and Surface Engineering.”